Videos on Handling & Processing of Powder & Bulk Solids

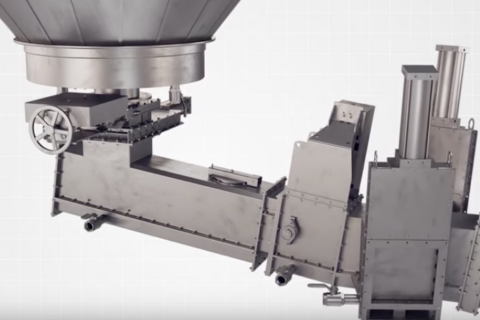

The Vortex® Quantum Orifice Gate™ is specifically engineered to handle dry bulk solids in gravity flow, dilute phase, or vacuum conveying systems with pressures up to 15 psig (1 barg) depending on size. Traditional slide gates and butterfly valves commonly allow packing of material, which prevents positive air and material shutoff.

Unlike common knife gates and butterfly valves, the Orifice Gate is specifically engineered to handle dry bulk powders, pellets, and granules. Knife gates rely on soft elastomeric seals which erode or tear away in service. Butterfly valves incorporate discs that cause significant flow restrictions, thus impacting system performance and throughput. Both designs promote wedging and packing of materials, preventing positive air and material shut off. The Orifice Gate eliminates design flaws associated with knife gates and butterfly valves.

Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles

Rated for ATEX Zone 0/20 internal and Zone 1/21 external

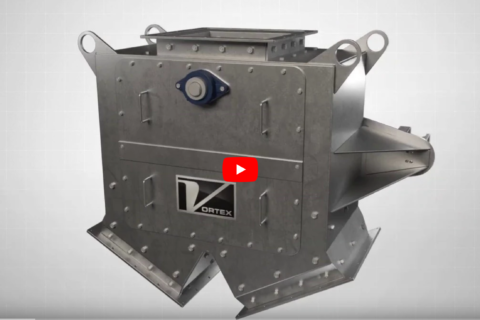

Vortex – Solids & Bulk Handling Components

Vortex – Solids & Bulk Handling Components

**********

Vortex Videos

shown on the Powder Bulk Videos Portal:

2. Vortex® Seal Tite Diverter™

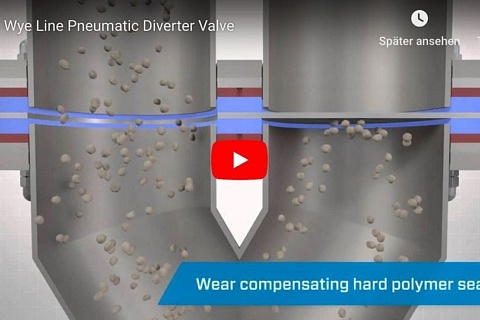

3. Vortex™® Wye Line Diverter™

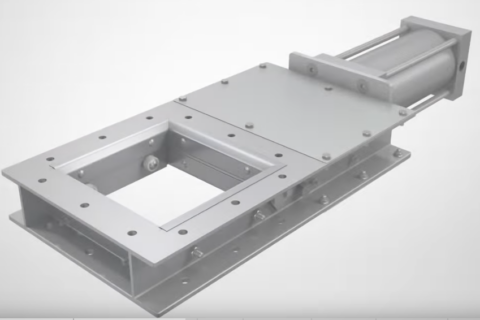

4. Vortex® Orifice Slide Gate Valve™

5. Vortex® Telescopic Loading Spout

6. Vortex® Aerated Conveying System

7. Vortex® Roller Slide Gate Valve™

8. Vortex® Fill Pass Diverter™

9. Vortex® Flex Tube Diverter™

10. Vortex® Pivoting Chute Diverter™

**********

Visit Homepage

**********

More Videos by Vortex

FEATURED VIDEOS

Views started Jan. 1, 2024Top 15 Videos

- VAC-U-MAX: Direct Charge Blender Loading(TM) Whiteboard Video (11,118)

- Schenck Process: Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF (11,059)

- Enge Plas Automation – Corporate Video 2023 (11,054)

- DSH Systems: Introduction (10,993)

- Laidig Systems: Applications – Powder and Bulk Solids (10,961)

- DSH Systems: Installation Profile – Phu My Port in Vietnam (10,876)

- Vortex® Aerated Conveying System (10,863)

- REMBE®: Safety_Campus® –industrial – Flameless Explosion Venting (10,854)

- DSH Systems: Before & After DSH7 Truck Loading Limestone Sand (10,850)

- REMBE®: Safety_Campus® – industrial – REMBE CO. Pilot (10,844)

- Schenck Process: Cement Mixing and Blending with MULTICOR® (10,822)

- Schenck Process: E-finity Dense Phase Conveying (10,787)

- Schenck Process: Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels (10,779)

- Schenck Process: Kibbler Heavy Duty Mill – Kemutec KEK – Food Breaker & Grinder (10,775)

- Schenck Process: Universal Mill for Fine Grinding of Powders – KEK Kemutec (10,748)