Videos on Handling & Processing of Powder & Bulk Solids

Dense Phase Pneumatic Conveying from Schenck Process , are an effective, simple and highly reliable solution for handling Powders and Fly Ash. This video shows the Multi PD Dense Phase Pumps in use.

They incorporates a Dome Valve, which is the only moving part in the vessel; ensuring the system’s reliability and low maintenance operation.

The pumps move the fly ash or powder, from ESPs or from bag filters and can be used to convey directly to the main silos without using an intermediate hopper. There can be up to 8 pumps connected on the same pipeline with an ESP.

The Multi PD pump system is able to convey distances up to 750m, at rates of upto 200 tph – thereby at higher conveying velocities than with the standard Multi Dense Phase vessels. The Multi PD system also has lower specific air consumption and uses smaller pipe sizes to achieve the same conveying rate compared with a standard Multi Dense Phase system.

For more information on Pneumatic Conveyors,

please email: [email protected]

**********

Schenck Process Videos

shown on the Powder Bulk Videos Portal:

1. Schenck Process:

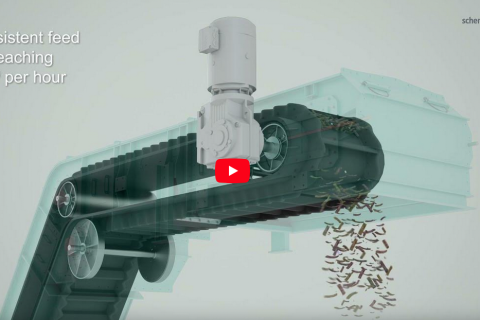

Sustainable Feeding of Alternative Fuels in Cement with MultiFlex Feeder

2. Schenck Process:

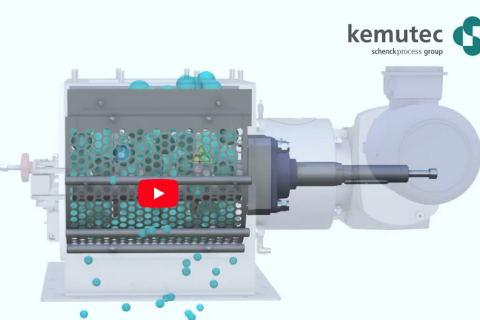

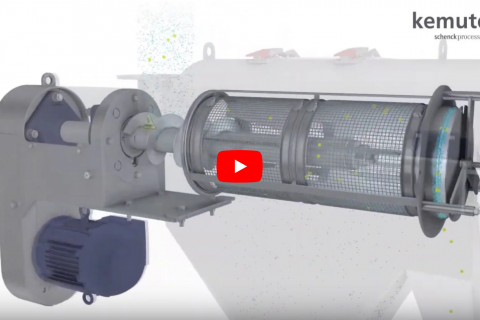

Universal Mill for Fine Grinding of Powders | KEK Kemutec

3. Schenck Process:

Centrifugal Sifter

Hygienic Design & Sifts High Volume

Kemutec KEK

4. Schenck Process:

Granulation Grinding Cone Mill Machine

from Kemutec for Gentle Milling

5. Schenck Process:

MCF Air Filtration for a Dust Free Environment

6. Schenck Process:

Kibbler Heavy Duty Mill –

Kemutec KEK – Food Breaker & Grinder

7. Schenck Process:

E-finity Dense Phase Conveying

8. Schenck Process:

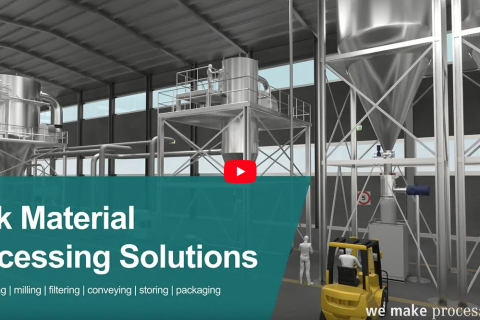

Bulk Material Handling Solutions for Food and Dairy Applications

9. Schenck Process:

Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF

10. Schenck Process:

Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels

11. Schenck Process:

Cement Mixing and Blending with MULTICOR®

More Videos by Schenck Process Group Videos

FEATURED VIDEOS

Views started Jan. 1, 2024Top 15 Videos

- VAC-U-MAX: Direct Charge Blender Loading(TM) Whiteboard Video (11,118)

- Schenck Process: Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF (11,059)

- Enge Plas Automation – Corporate Video 2023 (11,054)

- DSH Systems: Introduction (10,993)

- Laidig Systems: Applications – Powder and Bulk Solids (10,961)

- DSH Systems: Installation Profile – Phu My Port in Vietnam (10,876)

- Vortex® Aerated Conveying System (10,863)

- REMBE®: Safety_Campus® –industrial – Flameless Explosion Venting (10,854)

- DSH Systems: Before & After DSH7 Truck Loading Limestone Sand (10,850)

- REMBE®: Safety_Campus® – industrial – REMBE CO. Pilot (10,844)

- Schenck Process: Cement Mixing and Blending with MULTICOR® (10,822)

- Schenck Process: E-finity Dense Phase Conveying (10,787)

- Schenck Process: Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels (10,779)

- Schenck Process: Kibbler Heavy Duty Mill – Kemutec KEK – Food Breaker & Grinder (10,775)

- Schenck Process: Universal Mill for Fine Grinding of Powders – KEK Kemutec (10,748)