Videos on Handling & Processing of Powder & Bulk Solids

The Enclosed Belt Conveyor and Elevator from Schenck Process, is designed to provide a cleaner, more efficient method of transporting material and is commonly seen in the Cement industry, including those using alternative fuels.

Branded the MoveMaster BEX, it features a closed, dust-tight belt elevator with a UNIQUE conveyor belt. Capable of conveying angles of 75ﹾ, it offers a consistent feed rate up to 390m³ per hour.

A dual end belt tensioning system and integrated cleaning solution, prevents product from building up. A secondary chain conveyor, recycles material from the over-carry, while a patented lever chain tensioning system, enhances the longevity of the chain and lowers typical maintenance requirements.

Ensuring significantly easier maintenance in comparison to other solutions, the MoveMaster BEX Enclosed Belt Conveyor & Elevator, provides very easy to remove parts and long-life performance, in addition to simpler in-situ maintenance.

For more information email:

[email protected]

**********

Schenck Process Videos

shown on the Powder Bulk Videos Portal:

1. Schenck Process:

Sustainable Feeding of Alternative Fuels in Cement with MultiFlex Feeder

2. Schenck Process:

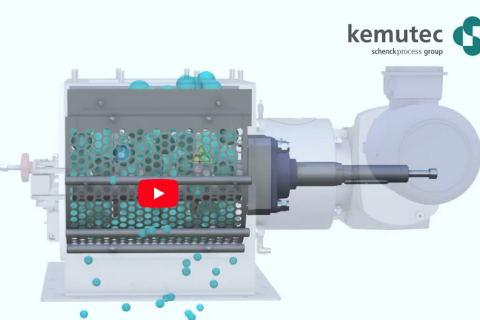

Universal Mill for Fine Grinding of Powders | KEK Kemutec

3. Schenck Process:

Centrifugal Sifter

Hygienic Design & Sifts High Volume

Kemutec KEK

4. Schenck Process:

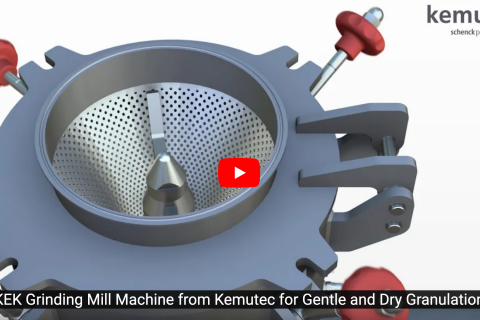

Granulation Grinding Cone Mill Machine

from Kemutec for Gentle Milling

5. Schenck Process:

MCF Air Filtration for a Dust Free Environment

6. Schenck Process:

Kibbler Heavy Duty Mill –

Kemutec KEK – Food Breaker & Grinder

7. Schenck Process:

E-finity Dense Phase Conveying

8. Schenck Process:

Bulk Material Handling Solutions for Food and Dairy Applications

9. Schenck Process:

Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF

10. Schenck Process:

Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels

11. Schenck Process:

Cement Mixing and Blending with MULTICOR®

More Videos by Schenck Process Group Videos

FEATURED VIDEOS

Views started Jan. 1, 2024Top 15 Videos

- VAC-U-MAX: Direct Charge Blender Loading(TM) Whiteboard Video (11,119)

- Schenck Process: Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF (11,060)

- Enge Plas Automation – Corporate Video 2023 (11,055)

- DSH Systems: Introduction (10,994)

- Laidig Systems: Applications – Powder and Bulk Solids (10,962)

- DSH Systems: Installation Profile – Phu My Port in Vietnam (10,877)

- Vortex® Aerated Conveying System (10,864)

- REMBE®: Safety_Campus® –industrial – Flameless Explosion Venting (10,855)

- DSH Systems: Before & After DSH7 Truck Loading Limestone Sand (10,851)

- REMBE®: Safety_Campus® – industrial – REMBE CO. Pilot (10,845)

- Schenck Process: Cement Mixing and Blending with MULTICOR® (10,823)

- Schenck Process: E-finity Dense Phase Conveying (10,788)

- Schenck Process: Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels (10,780)

- Schenck Process: Kibbler Heavy Duty Mill – Kemutec KEK – Food Breaker & Grinder (10,776)

- Schenck Process: Universal Mill for Fine Grinding of Powders – KEK Kemutec (10,749)