Videos on Handling & Processing of Powder & Bulk Solids

Schenck Process partners with cement producers to maximize revenue, improve handling processes, and drive production in the most sustainable and environmentally friendly manner.

Our solutions are designed to achieve the most economic and efficient cement production, covering each stage; from reception, storage, feeding, weighing, blending, conveying, and air filtration.

Most importantly, for those looking to reduce emissions and improve their sustainability contributions, our systems are designed for flexible processing of alternative fuels and SCM/CKD.

Key Benefits:

– 0.5% feeding accuracy of coal, kiln feed, CKD & SCM

– Reduced energy consumption

– Reduced cost

– High strength/quality

Environmental Benefits:

– Saves natural resources

– Reduces emissions and carbon footprint

– Improves sustainability

– Facilitates the use of alternative fuels

Cement Production Cost Savings through the Manufacturing Pull Principle Normal cement production processes are based on producing and storing goods in the expectation of them being consumed and in manufacturing terms, which is characterized as a ‘Push’ principle. The ‘Manufacturing Push’ principle can be an inefficient use of both resources and capital, resulting in increased inventory/stock levels and the tying up of cash.

The Schenck Process MULTICOR® Blending System solves this problem and facilitates the ‘Manufacturing Pull’ principle by only producing goods when they are ordered — no need for the cement manufacturer to store blended cement production in the expectation of consumption.

Mixing according to the “Just in time” principle, a rotating measuring wheel mixes the main components and additives directly in the MULTICOR® S and MULTICOR® H according to the Coriolis principle. No separate mixer is required, and any mixture can be produced. This saves costs that would otherwise be incurred by using intermediate transport technology and silos.

Learn more at:

https://www.schenckprocess.com/technologies/weighing/mass-flow-meters

**********

Schenck Process Videos

shown on the Powder Bulk Videos Portal:

1. Schenck Process:

Sustainable Feeding of Alternative Fuels in Cement with MultiFlex Feeder

2. Schenck Process:

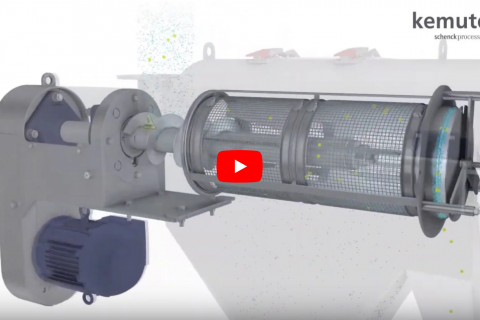

Universal Mill for Fine Grinding of Powders | KEK Kemutec

3. Schenck Process:

Centrifugal Sifter

Hygienic Design & Sifts High Volume

Kemutec KEK

4. Schenck Process:

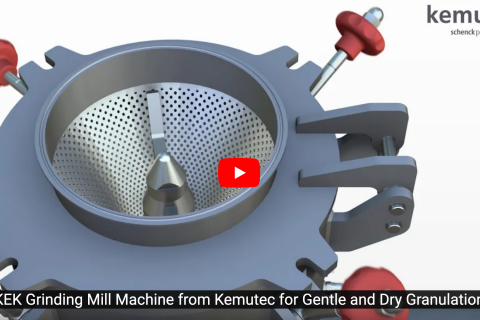

Granulation Grinding Cone Mill Machine

from Kemutec for Gentle Milling

5. Schenck Process:

MCF Air Filtration for a Dust Free Environment

6. Schenck Process:

Kibbler Heavy Duty Mill –

Kemutec KEK – Food Breaker & Grinder

7. Schenck Process:

E-finity Dense Phase Conveying

8. Schenck Process:

Bulk Material Handling Solutions for Food and Dairy Applications

9. Schenck Process:

Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF

10. Schenck Process:

Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels

11. Schenck Process:

Cement Mixing and Blending with MULTICOR®

More Videos by Schenck Process Group Videos

FEATURED VIDEOS

Views started Jan. 1, 2024Top 15 Videos

- VAC-U-MAX: Direct Charge Blender Loading(TM) Whiteboard Video (11,119)

- Schenck Process: Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF (11,060)

- Enge Plas Automation – Corporate Video 2023 (11,055)

- DSH Systems: Introduction (10,994)

- Laidig Systems: Applications – Powder and Bulk Solids (10,962)

- DSH Systems: Installation Profile – Phu My Port in Vietnam (10,877)

- Vortex® Aerated Conveying System (10,864)

- REMBE®: Safety_Campus® –industrial – Flameless Explosion Venting (10,855)

- DSH Systems: Before & After DSH7 Truck Loading Limestone Sand (10,851)

- REMBE®: Safety_Campus® – industrial – REMBE CO. Pilot (10,845)

- Schenck Process: Cement Mixing and Blending with MULTICOR® (10,823)

- Schenck Process: E-finity Dense Phase Conveying (10,788)

- Schenck Process: Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels (10,780)

- Schenck Process: Kibbler Heavy Duty Mill – Kemutec KEK – Food Breaker & Grinder (10,776)

- Schenck Process: Universal Mill for Fine Grinding of Powders – KEK Kemutec (10,749)