Videos on Handling & Processing of Powder & Bulk Solids

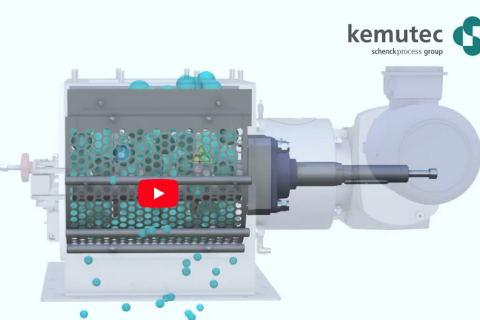

Kemutec’s Centrifugal Sifter, KEK, provides the ideal screening solution for powder and granules.

The Sifter is used to sift and screen high volumes of material, at high speed and with greater efficiency in comparison to other sifters.

Centrifugal sifters are typically used in the food processing and powder processing industries.

Incorporating a unique and easy clean ‘Cantilever’ design, the KEK Centrifugal Sifter ensures high standards of hygiene that are unprecedented and ease of operation. The Sifter’s design also allows for QUICK 30 second screen changes.

A Centrifugal Sifter is used to sift and screen high volumes of material, at high speed and with greater efficiency in comparison to other sifters used by material producers, such as Food producers, as well as Pharmaceuticals and Chemical manufacturers.

The process of Sifting material not only allows for size classification; separating material that isn’t of the required size, but also ensures a ‘screening process’ by removing unwanted material and de-risking powder handling.

Rotary Sifters is also a common name for this type of centrifugal processing machine, as can be a Flour Sifter or Powder. The sieving process of powders and granules takes place in gravity and in-line applications, while output with KEK varies from over 90 tonnes per hour, down to a few kilograms.

Kemutec’s KEK Centrifugal Sifters provide the ideal sifting and screening solution for dry powder and other bulk solids. A specialised ‘Cantilever’ design offers users unprecedented, high standards in hygiene. This is achieved through the machine’s easy access and rapid screen change functionality, averaging at just 30 seconds.

Through extensive experience, Kemutec were the FIRST designer of powder processing equipment to engineer the ‘Cantilever’ feature.

Designed to help allow tool free maintenance, this feature results in optimised uptime and output. In addition to this, KEK Sifters are very easy to operate, making the sifting and screening process simple for the operator.

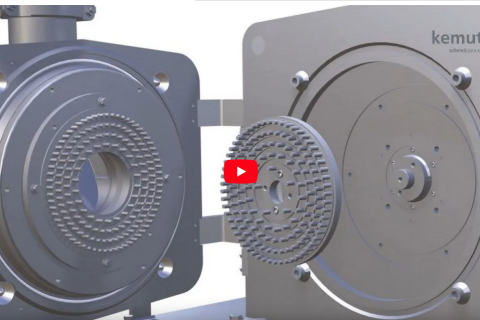

To sift a variety of materials, KEK Screens vary in size and construction. The Mesh Screen is ‘hand-made’ for high performance, making it renowned for supreme quality as well as durability.

- Hygienic and efficient processing

- Cleaning is easy and quick

- Replacing the screen is simple

- Paddle and scroll are easy to remove

- NEW paddle assembly design to provide an even more advanced hygienic view

- Easily inspect material through a machine panel

Typically used in food processing, as well as powder processing industries, the need for a hygienic design is paramount. This therefore makes KEK with its unique ‘Cantilever’ design, the best solution.

**********

Schenck Process Videos

shown on the Powder Bulk Videos Portal:

1. Schenck Process:

Sustainable Feeding of Alternative Fuels in Cement with MultiFlex Feeder

2. Schenck Process:

Universal Mill for Fine Grinding of Powders | KEK Kemutec

3. Schenck Process:

Centrifugal Sifter

Hygienic Design & Sifts High Volume

Kemutec KEK

4. Schenck Process:

Granulation Grinding Cone Mill Machine

from Kemutec for Gentle Milling

5. Schenck Process:

MCF Air Filtration for a Dust Free Environment

6. Schenck Process:

Kibbler Heavy Duty Mill –

Kemutec KEK – Food Breaker & Grinder

7. Schenck Process:

E-finity Dense Phase Conveying

8. Schenck Process:

Bulk Material Handling Solutions for Food and Dairy Applications

9. Schenck Process:

Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF

10. Schenck Process:

Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels

11. Schenck Process:

Cement Mixing and Blending with MULTICOR®

More Videos by Schenck Process Group Videos

FEATURED VIDEOS

Views started Jan. 1, 2024Top 15 Videos

- VAC-U-MAX: Direct Charge Blender Loading(TM) Whiteboard Video (11,121)

- Schenck Process: Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF (11,061)

- Enge Plas Automation – Corporate Video 2023 (11,056)

- DSH Systems: Introduction (10,995)

- Laidig Systems: Applications – Powder and Bulk Solids (10,963)

- DSH Systems: Installation Profile – Phu My Port in Vietnam (10,878)

- Vortex® Aerated Conveying System (10,865)

- REMBE®: Safety_Campus® –industrial – Flameless Explosion Venting (10,856)

- DSH Systems: Before & After DSH7 Truck Loading Limestone Sand (10,852)

- REMBE®: Safety_Campus® – industrial – REMBE CO. Pilot (10,846)

- Schenck Process: Cement Mixing and Blending with MULTICOR® (10,824)

- Schenck Process: E-finity Dense Phase Conveying (10,789)

- Schenck Process: Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels (10,781)

- Schenck Process: Kibbler Heavy Duty Mill – Kemutec KEK – Food Breaker & Grinder (10,777)

- Schenck Process: Universal Mill for Fine Grinding of Powders – KEK Kemutec (10,750)