Videos on Handling & Processing of Powder & Bulk Solids

For granulation applications – the Kemutec KEK Grinding Cone Mill is recognised as one of the most versatile size reduction grinding mill machines in the food and powder processing industry. It operates gently to protect the material and is used for both wet and dry granulation, such as fatty, heat sensitive, sticky, moist or otherwise difficult to grind products. It is also often used for gently re-grinding material.

The KEK Cone Mill provides a gentle low energy form of size reduction and eliminates traditional milling problems including noise, dust, and heat. The gentle grinding action is capable of control within fine limits while maintaining a close particle size distribution with minimal fines generation, typically grinding from 25 mm to 250 µm.

**********

Schenck Process Videos

shown on the Powder Bulk Videos Portal:

1. Schenck Process:

Sustainable Feeding of Alternative Fuels in Cement with MultiFlex Feeder

2. Schenck Process:

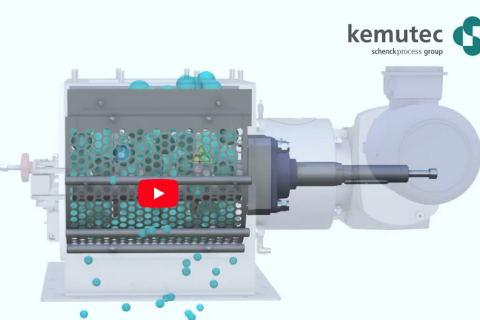

Universal Mill for Fine Grinding of Powders | KEK Kemutec

3. Schenck Process:

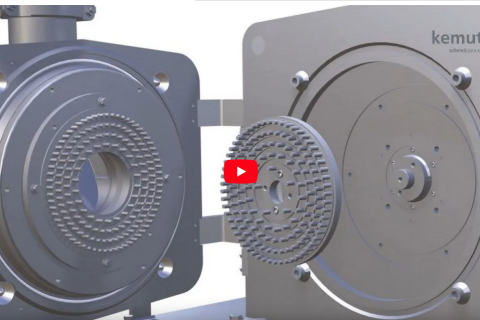

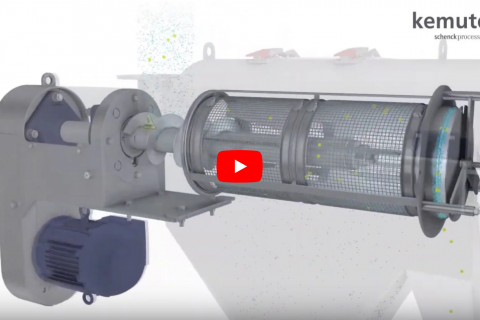

Centrifugal Sifter

Hygienic Design & Sifts High Volume

Kemutec KEK

4. Schenck Process:

Granulation Grinding Cone Mill Machine

from Kemutec for Gentle Milling

5. Schenck Process:

MCF Air Filtration for a Dust Free Environment

6. Schenck Process:

Kibbler Heavy Duty Mill –

Kemutec KEK – Food Breaker & Grinder

7. Schenck Process:

E-finity Dense Phase Conveying

8. Schenck Process:

Bulk Material Handling Solutions for Food and Dairy Applications

9. Schenck Process:

Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF

10. Schenck Process:

Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels

11. Schenck Process:

Cement Mixing and Blending with MULTICOR®

More Videos by Schenck Process Group Videos

FEATURED VIDEOS

Views started Jan. 1, 2024Top 15 Videos

- VAC-U-MAX: Direct Charge Blender Loading(TM) Whiteboard Video (11,119)

- Schenck Process: Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF (11,060)

- Enge Plas Automation – Corporate Video 2023 (11,055)

- DSH Systems: Introduction (10,994)

- Laidig Systems: Applications – Powder and Bulk Solids (10,962)

- DSH Systems: Installation Profile – Phu My Port in Vietnam (10,877)

- Vortex® Aerated Conveying System (10,864)

- REMBE®: Safety_Campus® –industrial – Flameless Explosion Venting (10,855)

- DSH Systems: Before & After DSH7 Truck Loading Limestone Sand (10,851)

- REMBE®: Safety_Campus® – industrial – REMBE CO. Pilot (10,845)

- Schenck Process: Cement Mixing and Blending with MULTICOR® (10,823)

- Schenck Process: E-finity Dense Phase Conveying (10,788)

- Schenck Process: Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels (10,780)

- Schenck Process: Kibbler Heavy Duty Mill – Kemutec KEK – Food Breaker & Grinder (10,776)

- Schenck Process: Universal Mill for Fine Grinding of Powders – KEK Kemutec (10,749)