Videos on Handling & Processing of Powder & Bulk Solids

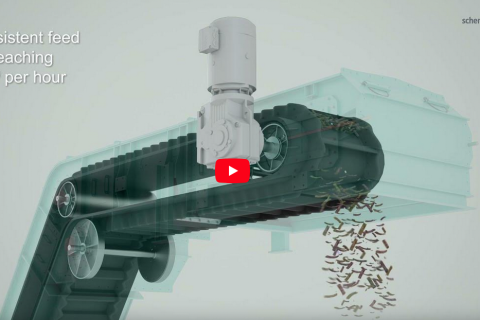

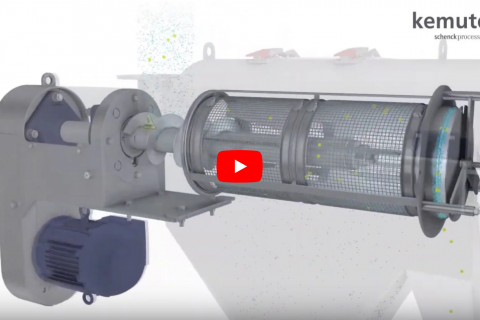

Kemutec’s KEK Kibbler are heavy duty mills that are designed to grind large lumps of material up to 6″ and reduce them down to 1/8″ in preparation for further processing. They are commonly used as a form of granulation in the food processing and power industries.

The size reduction process takes place through a combination of impact, crushing, cutting and abrasion. The heavy-duty beater sweeps product against the contoured grinding screen, at a steady rate.

– Robust, heavy duty mill

– Ensures consistent milled particle size

– Easy size classification via interchangeable screens

– High turning effect, at slow speed, for effective, safe pre-breaking

– Design offers enhanced hygiene and easy, quick cleaning

– Quick screen changes, allowed through non-drive end access door

– Minimises noise, heat and fines generation

Read more: https://www.kemutec.com/product/kek-k…

Kemutec is a brand, part of Schenck Process

www.kemutec.com

+44 (0)1625 412000

**********

Schenck Process Videos

shown on the Powder Bulk Videos Portal:

1. Schenck Process:

Sustainable Feeding of Alternative Fuels in Cement with MultiFlex Feeder

2. Schenck Process:

Universal Mill for Fine Grinding of Powders | KEK Kemutec

3. Schenck Process:

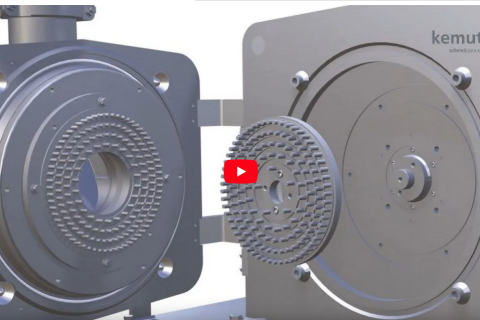

Centrifugal Sifter

Hygienic Design & Sifts High Volume

Kemutec KEK

4. Schenck Process:

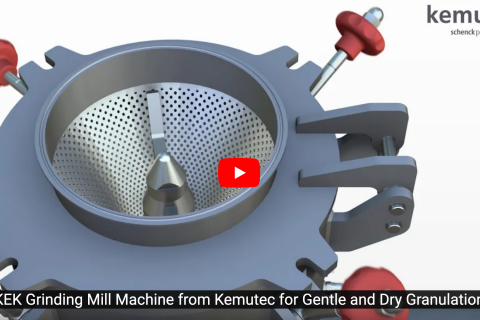

Granulation Grinding Cone Mill Machine

from Kemutec for Gentle Milling

5. Schenck Process:

MCF Air Filtration for a Dust Free Environment

6. Schenck Process:

Kibbler Heavy Duty Mill –

Kemutec KEK – Food Breaker & Grinder

7. Schenck Process:

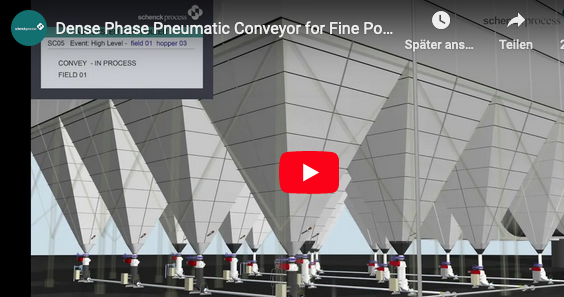

E-finity Dense Phase Conveying

8. Schenck Process:

Bulk Material Handling Solutions for Food and Dairy Applications

9. Schenck Process:

Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF

10. Schenck Process:

Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels

11. Schenck Process:

Cement Mixing and Blending with MULTICOR®

More Videos by Schenck Process Group Videos

FEATURED VIDEOS

Views started Jan. 1, 2024Top 15 Videos

- VAC-U-MAX: Direct Charge Blender Loading(TM) Whiteboard Video (11,122)

- Schenck Process: Rotary Valve for Feeding Alternative Fuels in Cement – MultiCell AF (11,062)

- Enge Plas Automation – Corporate Video 2023 (11,057)

- DSH Systems: Introduction (10,996)

- Laidig Systems: Applications – Powder and Bulk Solids (10,964)

- DSH Systems: Installation Profile – Phu My Port in Vietnam (10,879)

- Vortex® Aerated Conveying System (10,866)

- REMBE®: Safety_Campus® –industrial – Flameless Explosion Venting (10,857)

- DSH Systems: Before & After DSH7 Truck Loading Limestone Sand (10,853)

- REMBE®: Safety_Campus® – industrial – REMBE CO. Pilot (10,847)

- Schenck Process: Cement Mixing and Blending with MULTICOR® (10,825)

- Schenck Process: E-finity Dense Phase Conveying (10,790)

- Schenck Process: Enclosed Belt Conveyor & Elevator for Cement & Alternative Fuels (10,782)

- Schenck Process: Kibbler Heavy Duty Mill – Kemutec KEK – Food Breaker & Grinder (10,778)

- Schenck Process: Universal Mill for Fine Grinding of Powders – KEK Kemutec (10,751)